About Pump Energy Calculator (Formula)

The Pump Energy Calculator is an essential tool for engineers, operators, and facility managers looking to optimize energy usage in pumping systems. It helps determine the energy consumed by pumps over a specified period, allowing for better energy management and cost savings. By understanding how to calculate energy requirements, users can make informed decisions regarding pump selection, operation, and maintenance. This article will delve into the formula used in this calculation, provide detailed instructions on how to use the calculator, illustrate an example, and answer frequently asked questions about pump energy.

Formula

The formula for calculating pump energy is:

Epump = AP * T * 60

where Epump represents the energy consumed by the pump in kilowatt-hours (kWh), AP is the power of the pump in horsepower (HP), and T is the time in hours.

How to Use

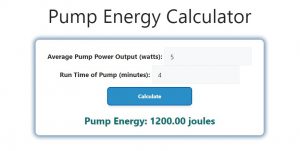

To effectively use the Pump Energy Calculator, follow these steps:

- Gather Data: Collect the necessary information, including the power rating of the pump in horsepower (AP) and the total operating time in hours (T).

- Input Values: Enter the values for AP and T into the calculator.

- Calculate Pump Energy: Click the calculate button. The calculator will process the input and provide the total energy consumed (Epump) in kilowatt-hours.

Example

Let’s consider an example where the power of the pump (AP) is 5 horsepower and the operating time (T) is 4 hours. To calculate the energy consumption:

- Use the formula:

Epump = AP * T * 60

Epump = 5 * 4 * 60

Epump = 5 * 240

Epump = 1200 kWh.

Thus, the pump would consume 1200 kilowatt-hours of energy.

FAQs

- What is pump energy?

Pump energy refers to the amount of energy consumed by a pump during its operation, typically measured in kilowatt-hours. - Why is it important to calculate pump energy?

Calculating pump energy helps in understanding operational costs, optimizing performance, and reducing energy waste. - What does AP stand for in the formula?

AP stands for the power rating of the pump, measured in horsepower (HP). - What does T represent?

T represents the total operating time of the pump, measured in hours. - How is pump energy measured?

Pump energy is typically measured in kilowatt-hours (kWh). - Can I use this calculator for any type of pump?

Yes, the calculator can be used for various types of pumps, including centrifugal, positive displacement, and submersible pumps. - How can I reduce energy consumption in pumping systems?

Energy consumption can be reduced by optimizing pump selection, maintaining equipment, and employing variable speed drives. - What factors can affect pump energy consumption?

Factors include pump efficiency, fluid properties, system pressure, and the operating conditions of the pump. - Is it necessary to convert horsepower to kilowatts?

No, the calculator automatically accounts for the conversion in the formula, simplifying the process for users. - How do I interpret the results from the Pump Energy Calculator?

The result indicates the total energy consumption over the specified time, helping you assess costs and efficiency. - Are there tools to measure real-time pump energy consumption?

Yes, there are energy monitoring devices that can track real-time energy consumption and efficiency of pumps. - Can I input decimal values for horsepower and time?

Yes, the calculator accepts decimal values for more precise calculations. - What should I do if my pump operates intermittently?

Calculate the total operating time across all cycles to get an accurate energy consumption estimate. - Does pump size affect energy consumption?

Yes, larger pumps generally consume more energy, but efficiency varies based on design and operation. - Can I use this calculator for other electrical equipment?

This calculator is specifically designed for pumps; however, similar principles can be applied to other machinery with modifications. - How often should I monitor pump energy consumption?

Regular monitoring is recommended, especially if you notice changes in performance or energy bills. - What are the benefits of energy-efficient pumps?

Energy-efficient pumps can lead to significant cost savings, reduced environmental impact, and longer service life. - Do pump manufacturers provide energy consumption data?

Yes, most manufacturers provide performance data, including energy consumption under specific conditions. - What is the significance of a pump’s efficiency rating?

A higher efficiency rating indicates less energy wasted, leading to lower operational costs and improved performance. - What are some common issues that can increase pump energy consumption?

Issues like cavitation, blockage, and misalignment can lead to higher energy use; regular maintenance can help prevent these problems.

Conclusion

The Pump Energy Calculator is a valuable resource for anyone involved in the operation or management of pumping systems. By understanding the formula and how to use the calculator, users can effectively assess energy consumption, optimize their systems, and make informed decisions about their operations.