About Bct Calculator (Formula)

The BCT (Box Compression Test) Calculator is an essential tool for packaging engineers and manufacturers, allowing them to evaluate the strength and integrity of cardboard boxes. The BCT measures the maximum weight a box can withstand before collapsing, which is crucial for ensuring that products are safely transported and stored. Understanding how to effectively use the BCT Calculator can lead to improved packaging designs and reduced shipping costs. This article will delve into the formula for calculating BCT, provide guidance on how to use it, present a practical example, and address frequently asked questions about box compression tests.

Formula

The formula for calculating the Box Compression Test (BCT) is:

BCT = 5.876 * ECT * √(P * T)

Where:

- BCT represents the Box Compression Test value (in pounds).

- ECT is the Edge Crush Test value (in pounds per inch).

- P is the flat crush test value (in pounds).

- T is the box’s wall thickness (in inches).

How to Use

To utilize the BCT Calculator effectively, follow these steps:

- Determine the ECT Value: Measure or obtain the Edge Crush Test value for the cardboard material used in the box. This can usually be found on the box specifications or by conducting an ECT test.

- Measure the Flat Crush Test Value: Obtain the flat crush test value (P) for the cardboard material. This value can be sourced from lab tests or manufacturer specifications.

- Measure the Wall Thickness: Measure the wall thickness (T) of the box in inches. For double-walled boxes, ensure you measure the thickness of the combined walls.

- Input Values into the Formula: Substitute the ECT, P, and T values into the formula BCT = 5.876 * ECT * √(P * T).

- Calculate BCT: Perform the calculation to determine the box compression strength.

- Interpret the Results: Use the calculated BCT value to evaluate if the box can adequately support the intended weight during transportation and storage.

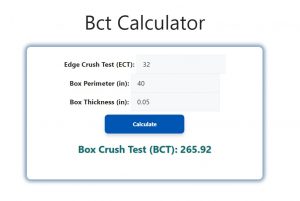

Example

Let’s say you have the following measurements:

- Edge Crush Test Value (ECT): 32 pounds per inch

- Flat Crush Test Value (P): 40 pounds

- Wall Thickness (T): 0.05 inches

Using the formula:

BCT = 5.876 * ECT * √(P * T)

BCT = 5.876 * 32 * √(40 * 0.05)

BCT = 5.876 * 32 * √(2)

BCT ≈ 5.876 * 32 * 1.414

BCT ≈ 5.876 * 45.25

BCT ≈ 265.8 pounds

In this example, the box compression strength is approximately 265.8 pounds.

FAQs

- What is the BCT Calculator used for?

The BCT Calculator is used to determine the maximum weight a cardboard box can withstand before collapsing. - Why is BCT important in packaging?

BCT is crucial for ensuring that boxes can safely hold products during transportation and storage, preventing damage. - What is the Edge Crush Test (ECT)?

The ECT measures the ability of corrugated board to resist crushing forces, indicating its strength. - How do I conduct an Edge Crush Test?

An ECT can be conducted using a specialized testing machine that applies pressure to the edge of the corrugated board until it fails. - What factors influence BCT values?

Factors include the type of material used, wall thickness, and the design of the box. - Can I use the BCT Calculator for different types of cardboard?

Yes, the BCT Calculator can be used for any type of cardboard, as long as you have the appropriate ECT and flat crush test values. - How does wall thickness affect BCT?

Generally, thicker walls contribute to higher BCT values, making the box stronger and more capable of handling weight. - What is the typical range for BCT values?

BCT values vary widely depending on the box material and design, but they typically range from 150 to over 600 pounds. - Is BCT the same as the Box Compression Strength?

Yes, BCT is often referred to as box compression strength, and both terms are used interchangeably. - What can I do if my BCT value is too low?

Consider using stronger materials, increasing wall thickness, or redesigning the box to enhance its strength. - What role does packaging design play in BCT?

Packaging design can significantly affect BCT values; thoughtful design can enhance the box’s structural integrity. - Is it necessary to test every box type?

While it’s beneficial to test various box designs, you may only need to test a representative sample to ensure quality. - How often should BCT testing be performed?

Regular testing is recommended, especially when there are changes in material or design. - Can I estimate BCT without testing?

While you can estimate BCT using general material properties, accurate values should ideally be obtained through testing. - How do environmental factors affect BCT?

Humidity, temperature, and exposure to moisture can affect cardboard strength and, consequently, the BCT value. - Are there industry standards for BCT testing?

Yes, several organizations provide guidelines and standards for conducting BCT tests, including ASTM International. - What is the difference between BCT and CMT (Compression Test)?

BCT measures box strength under compression, while CMT assesses the material’s compressive strength. - Can I use the BCT Calculator for stacked boxes?

Yes, the BCT Calculator can help assess the strength of boxes that will be stacked during storage or transport. - What safety measures should I take during testing?

Always follow safety protocols, including wearing appropriate personal protective equipment (PPE) and using equipment correctly. - Where can I find more resources on box compression testing?

Many packaging associations and technical publications provide resources on BCT testing methods and standards.

Conclusion

The BCT Calculator is an invaluable resource for anyone involved in packaging design and testing. By using the formula BCT = 5.876 * ECT * √(P * T), you can accurately assess the compression strength of cardboard boxes, ensuring they meet the necessary standards for safe transportation and storage. This article has provided an overview of the formula, step-by-step instructions for use, and answers to common questions, empowering you to make informed decisions about your packaging needs.