About Pulsed Laser Average Power Calculator (Formula)

Pulsed lasers are widely used in various applications, including medical treatments, scientific research, and industrial processing. Understanding the average power of a pulsed laser is critical to ensuring the safety and effectiveness of the laser in use. The average power of a pulsed laser is calculated based on its peak power and duty cycle. This article provides the formula for calculating pulsed laser average power, a step-by-step guide on how to use the calculator, and answers frequently asked questions.

Formula

The formula to calculate pulsed laser average power (PLAP) is:

Pulsed Laser Average Power = Peak Power (PP) × Duty Cycle (DC)

Where:

- PLAP is the pulsed laser’s average power.

- PP is the peak power of the laser during its active phase.

- DC is the duty cycle, which is the ratio of the pulse duration to the total period of the laser operation.

How to Use

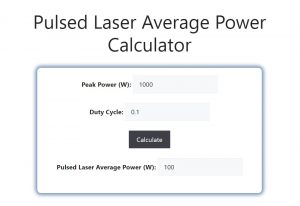

- Determine the peak power (PP) of the pulsed laser. This value is typically provided by the manufacturer.

- Determine the duty cycle (DC), which is the ratio of the pulse duration to the total pulse period.

- Input both values into the calculator, and it will compute the pulsed laser’s average power.

Example

Let’s assume you have the following values:

- Peak Power (PP) = 1000 W

- Duty Cycle (DC) = 0.1 (10%)

Using the formula:

Pulsed Laser Average Power = 1000 W × 0.1

Pulsed Laser Average Power = 100 W

This means that the average power output of the laser is 100 watts.

FAQs

- What is pulsed laser average power?

Pulsed laser average power refers to the time-averaged power output of a pulsed laser, calculated over both its on and off cycles. - What is peak power in a pulsed laser?

Peak power is the maximum power output of a laser during the active (on) portion of each pulse. - What is duty cycle in a pulsed laser?

Duty cycle is the ratio of the laser’s pulse duration (the time it is on) to the total pulse period (the combined on and off time). - How is duty cycle expressed?

Duty cycle is usually expressed as a percentage or a decimal value, where a 10% duty cycle means the laser is on 10% of the time and off 90% of the time. - Why is pulsed laser average power important?

Knowing the average power helps in determining the overall energy delivered during laser operations, which is crucial for safety and performance. - Can I use this formula for continuous lasers?

No, this formula is specific to pulsed lasers. Continuous lasers have constant output power, so the average power is the same as the output power. - How do pulse duration and frequency affect average power?

Shorter pulse durations and lower frequencies reduce the duty cycle, lowering the average power, while longer durations and higher frequencies increase the average power. - What is the difference between peak power and average power?

Peak power refers to the highest power output during a pulse, while average power considers both the active and inactive phases, providing an overall power output measure. - Why is the duty cycle used in the calculation?

The duty cycle accounts for the time the laser is actually on, allowing for an accurate calculation of the average power over the entire operation period. - What happens if the duty cycle is increased?

Increasing the duty cycle means the laser is on for a longer portion of the total pulse period, which increases the average power output. - How do I calculate the duty cycle?

Duty cycle can be calculated as: Duty Cycle = (Pulse Duration / Total Pulse Period). This ratio is then multiplied by 100 if expressed as a percentage. - Can this formula be used for ultrafast lasers?

Yes, as long as the laser operates in a pulsed mode, this formula can be applied, though ultrafast lasers often have very short pulse durations. - Does the material being targeted affect the average power calculation?

No, the material being targeted does not affect the average power calculation, but it may affect the absorption and reaction to the laser energy. - Is average power important for safety regulations?

Yes, understanding the average power is crucial for meeting safety standards and ensuring the laser does not exceed safe energy thresholds during operation. - How does frequency affect average power?

Higher pulse frequencies increase the duty cycle, which in turn increases the average power, while lower frequencies reduce it. - What units are used for peak power and average power?

Both peak power and average power are typically measured in watts (W). - Can I use this formula for multi-mode pulsed lasers?

Yes, the formula works for multi-mode lasers as long as the peak power and duty cycle for each mode are known. - How can I increase the average power of a pulsed laser?

To increase average power, you can either increase the peak power or increase the duty cycle by lengthening the pulse duration or increasing the pulse frequency. - What is the role of pulse width in determining duty cycle?

Pulse width (or pulse duration) is a key component in determining duty cycle, as it defines how long the laser is on during each pulse cycle. - Can this formula be used for medical lasers?

Yes, the formula is applicable to pulsed medical lasers, which often rely on controlling average power for safe and effective treatments.

Conclusion

Understanding pulsed laser average power is essential for safely and effectively using pulsed lasers in various applications. By using the formula that considers peak power and duty cycle, you can accurately calculate the average power and make informed decisions in both scientific and industrial settings. Whether you’re working with medical lasers or industrial-grade pulsed lasers, this calculation helps ensure optimal performance while maintaining safety standards.