About Heat Exchanger Area Calculator (Formula)

The Heat Exchanger Area Calculator is an essential tool for engineers and designers involved in thermal system design. Heat exchangers play a critical role in various applications, including HVAC systems, power plants, and chemical processing, by transferring heat between two or more fluids. Understanding the required heat exchanger area is crucial for optimizing performance, ensuring energy efficiency, and meeting system design specifications. This article provides a detailed overview of how to use the calculator, an example for better understanding, and answers to frequently asked questions related to heat exchanger area calculations.

Formula

The formula to calculate the heat exchanger area is:

A = C / (k * ΔT)

Where:

- A is the area of the heat exchanger (in square meters).

- C is the heat transfer rate (in watts).

- k is the overall heat transfer coefficient (in watts per square meter per degree Celsius).

- ΔT is the temperature difference between the two fluids (in degrees Celsius).

How to Use

- Gather Required Data: To use the Heat Exchanger Area Calculator, you will need:

- The heat transfer rate (C) in watts.

- The overall heat transfer coefficient (k) in watts per square meter per degree Celsius.

- The temperature difference (ΔT) between the two fluids in degrees Celsius.

- Input Values into the Formula: Substitute the values you gathered into the formula provided above.

- Calculate the Heat Exchanger Area: Perform the calculation to determine the required area of the heat exchanger.

- Interpret the Results: Use the calculated area to design the heat exchanger, ensuring it meets the thermal performance requirements of your application.

Example

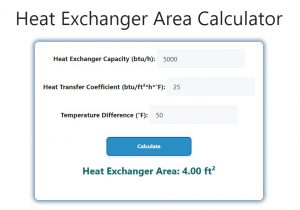

Let’s consider an example to illustrate the calculation of heat exchanger area.

- Given Data:

- Heat transfer rate (C) = 5000 watts

- Overall heat transfer coefficient (k) = 25 watts/m²°C

- Temperature difference (ΔT) = 50°C

Step 1: Input Values into the Formula

Using the formula A = C / (k * ΔT):

Step 2: Calculate A

A = 5000 / (25 * 50)

A = 5000 / 1250

A = 4 square meters

In this example, the required heat exchanger area is 4 square meters, indicating the surface area needed for effective heat transfer.

FAQs

- What is a heat exchanger?

A heat exchanger is a device that facilitates the transfer of heat between two or more fluids without mixing them. - Why is calculating heat exchanger area important?

It ensures that the heat exchanger can transfer sufficient heat to meet the requirements of the thermal system. - What units are used for heat exchanger area?

Heat exchanger area is typically measured in square meters (m²). - How do I determine the heat transfer rate (C)?

The heat transfer rate can be determined through thermal calculations based on the specific application and fluid properties. - What affects the overall heat transfer coefficient (k)?

Factors include the type of fluids, flow arrangement, temperature difference, and surface conditions of the heat exchanger. - What is the significance of ΔT in the formula?

ΔT represents the temperature difference between the inlet and outlet of the heat exchanger, crucial for determining heat transfer efficiency. - Can I use this calculator for any type of heat exchanger?

Yes, as long as you have the necessary parameters, the calculator can be applied to various heat exchanger types. - How can I improve the efficiency of a heat exchanger?

Consider optimizing flow rates, using better materials, and enhancing surface area through fins or other design modifications. - What are common types of heat exchangers?

Common types include shell and tube, plate, air-cooled, and double-pipe heat exchangers. - Is it necessary to insulate heat exchangers?

Insulating heat exchangers can improve energy efficiency by minimizing heat loss to the environment. - How do I select the right heat exchanger for my application?

Consider factors like heat transfer requirements, fluid properties, space constraints, and budget when selecting a heat exchanger. - What is the typical range for the overall heat transfer coefficient (k)?

The value of k can vary widely, typically ranging from 10 to 1000 watts/m²°C, depending on the fluids and design. - How often should heat exchangers be maintained?

Regular maintenance is essential; however, the frequency depends on the application and operating conditions. - What role does fluid velocity play in heat exchanger performance?

Higher fluid velocity generally enhances heat transfer by increasing turbulence, but it can also increase pressure drop. - Can fouling affect heat exchanger efficiency?

Yes, fouling can significantly reduce heat transfer efficiency by creating an insulating layer on heat transfer surfaces. - How do I measure the temperature difference (ΔT)?

Measure the inlet and outlet temperatures of each fluid in the heat exchanger to calculate ΔT. - What software tools are available for heat exchanger design?

Various software tools, like Aspen HYSYS and HTRI, can assist in the design and analysis of heat exchangers. - What is a counterflow heat exchanger?

In a counterflow heat exchanger, the two fluids flow in opposite directions, maximizing the temperature gradient and heat transfer. - Are there regulations regarding heat exchanger efficiency?

Yes, various industry standards and regulations may dictate minimum efficiency requirements for heat exchangers. - Where can I find more resources on heat exchanger design?

Resources can be found in engineering textbooks, online courses, and technical papers focusing on thermal systems and heat transfer.

Conclusion

The Heat Exchanger Area Calculator is a valuable tool for engineers and designers aiming to optimize the thermal performance of heat exchangers in various applications. By understanding the parameters that influence heat exchanger area, users can make informed design decisions that enhance efficiency and effectiveness. Utilizing this calculator along with the insights shared in this article, you can ensure that your heat exchangers meet the necessary performance standards for your specific application.