About Gearbox Efficiency Calculator (Formula)

The gearbox efficiency calculator is an essential tool for engineers and mechanics to determine how effectively a gearbox converts input power into output power. Gearboxes play a crucial role in various machinery, from automobiles to industrial equipment, and understanding their efficiency can help in optimizing performance, reducing energy loss, and prolonging the lifespan of mechanical systems. By calculating gearbox efficiency, you can identify potential areas for improvement, ensuring that your equipment operates smoothly and reliably.

Formula

The formula for calculating gearbox efficiency is:

Egear = (OT / (IT * GR)) * 100

Where:

- Egear represents the efficiency of the gearbox as a percentage.

- OT stands for the output torque provided by the gearbox.

- IT refers to the input torque applied to the gearbox.

- GR is the gear ratio of the gearbox, which is the ratio of the output speed to the input speed.

How to Use

To use the gearbox efficiency calculator, follow these steps:

- Gather Required Data: You will need the input torque (IT), output torque (OT), and the gear ratio (GR) for your specific gearbox.

- Input Values: Enter the values of OT, IT, and GR into the calculator.

- Calculate Efficiency: The calculator will apply the formula and provide you with the gearbox efficiency as a percentage.

- Interpret Results: Analyze the efficiency percentage to determine how effectively your gearbox is performing.

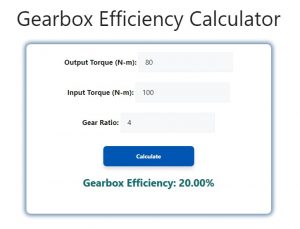

Example

Suppose you have a gearbox with the following specifications:

- Input Torque (IT) = 100 Nm

- Output Torque (OT) = 80 Nm

- Gear Ratio (GR) = 4

Using the formula:

Egear = (80 / (100 * 4)) * 100 = (80 / 400) * 100 = 20%

This means the gearbox has an efficiency of 20%, indicating that 20% of the input power is effectively converted to output power.

FAQs

- What is gearbox efficiency?

Gearbox efficiency measures how well a gearbox converts input power into output power, expressed as a percentage. - Why is gearbox efficiency important?

Understanding gearbox efficiency helps identify energy losses, improve performance, and extend the life of mechanical systems. - What does a low gearbox efficiency indicate?

A low efficiency suggests significant energy losses, which could be due to friction, wear, or improper lubrication. - How can I improve gearbox efficiency?

Improving lubrication, reducing friction, and using higher-quality components can enhance gearbox efficiency. - What factors affect gearbox efficiency?

Factors include gear design, material quality, lubrication, load conditions, and maintenance practices. - Is 100% gearbox efficiency achievable?

No, 100% efficiency is theoretically impossible due to inherent energy losses from friction and heat. - What is the typical efficiency range for gearboxes?

Most gearboxes have efficiencies ranging from 85% to 98%, depending on their design and application. - How often should I check gearbox efficiency?

Regular checks are recommended, especially in high-demand applications or when unusual noises or heat are detected. - What are the consequences of poor gearbox efficiency?

Poor efficiency can lead to increased energy costs, overheating, premature wear, and potential equipment failure. - Can gearbox efficiency be calculated without a calculator?

Yes, you can manually apply the formula, but using a calculator simplifies the process and reduces errors. - What is the gear ratio (GR)?

The gear ratio is the ratio of the output speed to the input speed, indicating how much torque is multiplied or reduced. - How does load affect gearbox efficiency?

Increased load can decrease efficiency due to higher friction and wear within the gearbox. - What maintenance practices can improve gearbox efficiency?

Regular lubrication, cleaning, and inspections can help maintain efficiency and prolong gearbox life. - Are there different types of gearboxes?

Yes, common types include bevel, helical, spur, and worm gearboxes, each with unique efficiency characteristics. - How do I know if my gearbox is operating efficiently?

Monitor the efficiency percentage; a significant drop from the expected value may indicate issues needing attention. - What tools are available for measuring gearbox efficiency?

In addition to calculators, efficiency can be assessed using torque meters and power analyzers. - Can gearbox efficiency affect overall machine performance?

Yes, inefficient gearboxes can lead to reduced machine performance, higher energy costs, and more frequent maintenance. - What role does lubrication play in gearbox efficiency?

Proper lubrication reduces friction, heat generation, and wear, all of which enhance efficiency. - What should I do if my gearbox efficiency is low?

Investigate potential issues, conduct maintenance, and consider redesigning or replacing components if necessary. - How does gearbox design impact efficiency?

Efficient designs minimize friction and maximize torque transfer, leading to improved overall performance.

Conclusion

The gearbox efficiency calculator is a valuable tool for anyone working with mechanical systems, allowing you to evaluate and optimize the performance of your gearboxes. By understanding and calculating gearbox efficiency, you can identify areas for improvement, ensure reliable operation, and enhance the lifespan of your machinery. Regularly monitoring gearbox efficiency helps maintain optimal performance and can lead to significant cost savings in energy and maintenance.