About Armature Resistance Calculator (Formula)

The Armature Resistance Calculator is a crucial tool for electrical engineers and technicians working with electric motors. Understanding armature resistance is essential for optimizing motor performance, improving efficiency, and troubleshooting issues in electrical circuits. The armature resistance (Ra) plays a significant role in determining how much voltage drop occurs within the motor when it is operating. By calculating this resistance, users can assess the performance of their electric motors and ensure they operate within their optimal parameters. This article will discuss how to use the calculator, provide an example, and answer frequently asked questions about armature resistance.

Formula

The formula for calculating armature resistance is:

Armature Resistance (Ra) = (Voltage (V) – Back E.M.F. (E)) / Current (I)

Where:

- Voltage (V) is the applied voltage to the motor.

- Back E.M.F. (E) is the electromotive force generated by the motor during operation.

- Current (I) is the current flowing through the armature winding.

How to Use

- Gather Necessary Data: To use the armature resistance calculator, you will need to collect the following data:

- The applied voltage (V) to the motor.

- The back electromotive force (E) generated by the motor.

- The current (I) flowing through the armature.

- Input Values into the Formula: Plug the gathered values into the formula to calculate the armature resistance.

- Calculate Armature Resistance: Perform the calculation to find the value of Ra. This will give you a clear understanding of the resistance in the armature winding.

- Analyze the Result: A lower armature resistance indicates better efficiency and performance, while a higher resistance may signal issues such as overheating or excessive losses in the motor.

Example

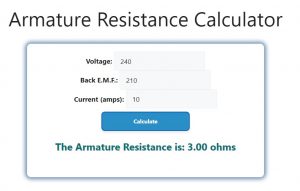

Let’s consider an example to illustrate how to calculate armature resistance.

- Given Data:

- Voltage (V) = 240 V

- Back E.M.F. (E) = 210 V

- Current (I) = 10 A

Step 1: Calculate Armature Resistance

Using the formula:

Armature Resistance (Ra) = (Voltage (V) – Back E.M.F. (E)) / Current (I)

Ra = (240 V – 210 V) / 10 A

Ra = 30 V / 10 A

Ra = 3 Ω

In this example, the armature resistance is 3 ohms, which indicates the resistance within the motor’s armature winding.

FAQs

- What is armature resistance?

Armature resistance is the resistance of the windings in an electric motor’s armature, which affects the motor’s efficiency and performance. - Why is armature resistance important?

It helps determine how much voltage drop occurs in the motor, influencing its overall performance and efficiency. - What does back E.M.F. represent?

Back E.M.F. (Electromotive Force) is the voltage generated by the motor due to its rotation, opposing the applied voltage. - How can I measure back E.M.F.?

Back E.M.F. can be calculated by measuring the voltage across the armature terminals while the motor is running. - What are the common units for measuring resistance?

Resistance is measured in ohms (Ω). - How does temperature affect armature resistance?

Armature resistance increases with temperature due to the increase in the resistivity of the conductor materials. - Can armature resistance be too high?

Yes, high armature resistance can lead to increased heating, reduced efficiency, and lower performance of the motor. - How often should I check armature resistance?

It is good practice to check armature resistance during routine maintenance or when experiencing motor performance issues. - What tools are needed to measure current and voltage?

You can use a multimeter to measure voltage and current accurately in a motor circuit. - How does armature resistance impact motor torque?

Higher armature resistance can reduce the torque produced by the motor because of increased voltage drop. - What is the typical range for armature resistance?

Typical armature resistance values can vary widely depending on the motor type and design, often ranging from a few ohms to several tens of ohms. - Can armature resistance affect starting current?

Yes, higher armature resistance can lead to higher starting currents, potentially causing damage to the motor or circuit. - Is it necessary to account for armature resistance in all motor calculations?

While not always critical, accounting for armature resistance is essential for precise calculations, especially in high-performance applications. - How does armature resistance relate to overall circuit resistance?

Armature resistance is a part of the total circuit resistance and affects the current flowing through the motor. - What can cause changes in armature resistance?

Wear, overheating, and damage to the windings can lead to changes in armature resistance. - Can I calculate armature resistance without measuring back E.M.F.?

While possible, it is not recommended, as back E.M.F. is critical for accurate calculations. - What should I do if my armature resistance is unusually high?

Investigate for potential issues such as damaged windings or overheating and consult a professional if necessary. - How does armature resistance affect energy loss?

Higher armature resistance results in greater energy losses in the form of heat, reducing the overall efficiency of the motor. - Is there a difference between armature resistance and field resistance?

Yes, armature resistance refers to the winding in the rotor, while field resistance pertains to the winding in the stator of the motor. - What role does armature resistance play in speed control?

Armature resistance influences the speed of the motor under load; higher resistance can limit maximum speed and affect speed regulation.

Conclusion

The Armature Resistance Calculator is an invaluable tool for understanding and optimizing the performance of electric motors. By accurately calculating armature resistance, users can diagnose issues, enhance motor efficiency, and ensure reliable operation. Knowing how to measure and interpret the results of armature resistance calculations is essential for electrical engineers and technicians in the field. With the information provided in this article, you are now equipped to assess armature resistance effectively and improve the performance of your electric motors.