About Stock Out Probability Calculator (Formula)

The Stock Out Probability Calculator is an essential tool for businesses that manage inventory, helping them assess the likelihood of running out of stock for a particular product. Stockouts can lead to lost sales, dissatisfied customers, and reduced profits. This calculator aids in making informed inventory decisions by providing a statistical estimate of stock out probability, allowing businesses to optimize their stock levels and improve customer satisfaction.

Formula

The formula for calculating stock out probability (PS) is:

PS = (ES / ED) * 100

Where:

- PS is the stock out probability.

- ES is the estimated stock out quantity.

- ED is the estimated demand.

How to Use

Using the Stock Out Probability Calculator is straightforward. Here’s how to utilize it effectively:

- Estimate Demand: Determine the expected demand for the product over a specific period. This can be based on historical sales data or market analysis.

- Estimate Stock Out Quantity: Estimate how much stock you are likely to run out of during that period. This requires understanding your current inventory levels and expected delivery times.

- Input Values: Enter the estimated stock out quantity (ES) and estimated demand (ED) into the calculator.

- Calculate Probability: The calculator will compute the stock out probability (PS) using the formula.

- Analyze Results: Review the probability percentage to make informed decisions about inventory restocking and management strategies.

Example

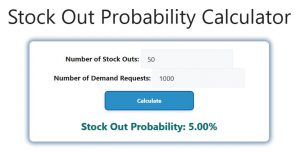

Let’s illustrate the use of the Stock Out Probability Calculator with a practical example.

Assume a company expects a demand of 1,000 units of a product over a month and estimates that they will run out of stock for 50 units.

Using the formula:

PS = (ES / ED) * 100

PS = (50 / 1000) * 100

PS = 0.05 * 100

PS = 5%

In this case, the stock out probability is 5%, indicating that there is a 5% chance of running out of stock during the month. This information can help the company decide whether to increase inventory levels.

FAQs

- What is stock out probability?

Stock out probability is the likelihood that a product will be out of stock when customers want to purchase it. - Why is calculating stock out probability important?

It helps businesses manage inventory effectively, minimize lost sales, and maintain customer satisfaction. - How is estimated demand determined?

Estimated demand can be based on historical sales data, market trends, and forecasts. - What factors influence stock out probability?

Factors include demand variability, lead times, current inventory levels, and supply chain disruptions. - Can stock out probability be reduced?

Yes, by optimizing inventory levels, improving demand forecasting, and enhancing supplier relationships. - What happens if stock out probability is too high?

A high stock out probability can lead to lost sales, unhappy customers, and damage to brand reputation. - How often should stock out probability be calculated?

It should be calculated regularly, especially during high-demand seasons or when introducing new products. - Is this calculator useful for all types of businesses?

Yes, it can benefit any business that maintains inventory, from retail to manufacturing. - What is the ideal stock out probability?

The ideal stock out probability is as low as possible, ideally below 5%, depending on the industry. - How can I improve demand estimation?

Use historical sales data, market analysis, and customer feedback to create more accurate demand forecasts. - What tools can assist in calculating stock out probability?

Inventory management software and demand forecasting tools can help streamline calculations and data analysis. - Does stock out probability vary by product?

Yes, it can vary significantly based on product demand patterns, seasonality, and market conditions. - Can I use this calculator for multiple products?

Yes, you can calculate stock out probabilities for multiple products separately to ensure comprehensive inventory management. - How does lead time affect stock out probability?

Longer lead times increase stock out probability as it takes more time to replenish inventory. - Is there a difference between stock out probability and service level?

Yes, stock out probability measures the chance of running out of stock, while service level refers to the target percentage of customer orders fulfilled without stockouts. - What are the consequences of stockouts?

Consequences include lost sales, decreased customer loyalty, and increased costs associated with expedited shipping for urgent restocking. - How can safety stock help mitigate stock out probability?

Maintaining safety stock provides a buffer against demand fluctuations and supply chain uncertainties, reducing the risk of stockouts. - Are there industry benchmarks for stock out probability?

Yes, benchmarks can vary by industry, so it’s helpful to research specific industry standards for optimal stock levels. - What is the relationship between stock out probability and inventory turnover?

Higher inventory turnover often leads to lower stock out probability as products are sold and replenished more frequently. - How can technology assist in managing stock out probability?

Technologies like inventory management systems, data analytics, and machine learning can enhance demand forecasting and inventory control.

Conclusion

The Stock Out Probability Calculator is a critical tool for effective inventory management. By accurately estimating the likelihood of stockouts, businesses can make informed decisions to optimize their inventory levels, reduce the risk of lost sales, and enhance customer satisfaction. Regularly calculating stock out probability enables companies to adapt to changing market conditions and maintain a competitive edge in their industry. By understanding and managing stock out risks, businesses can ensure a smoother operation and a more reliable supply chain.