About CFM to Static Pressure Calculator (Formula)

The CFM to Static Pressure Calculator is an essential tool for HVAC professionals and engineers involved in system design and airflow analysis. CFM, or cubic feet per minute, is a critical measurement of airflow, while static pressure is a vital indicator of system performance. Understanding the relationship between these two parameters helps ensure that HVAC systems operate efficiently and effectively. By using this calculator, users can easily determine the static pressure based on their airflow measurements, facilitating better system design and optimization.

Formula

The formula for calculating static pressure is:

Pstatic = Ptotal – ((CFM / A) / 4005)²

In this formula, Pstatic represents the static pressure, Ptotal is the total pressure in the system, CFM is the airflow rate, and A is the cross-sectional area of the duct.

How to Use

Using the CFM to Static Pressure Calculator is straightforward:

- Input Total Pressure (Ptotal): Enter the total pressure value in inches of water gauge (in. wg) or another appropriate unit.

- Input Airflow Rate (CFM): Enter the airflow rate in cubic feet per minute (CFM).

- Input Duct Area (A): Enter the cross-sectional area of the duct in square feet (ft²).

- Calculate: Click the “Calculate” button to determine the static pressure.

Example

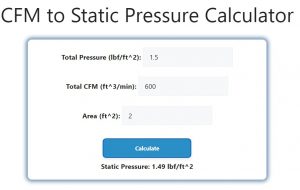

To illustrate the use of the CFM to Static Pressure Calculator, consider the following example:

- Total Pressure (Ptotal): 1.5 in. wg

- Airflow Rate (CFM): 600 CFM

- Duct Area (A): 2 ft²

Using the formula:

Pstatic = Ptotal – ((CFM / A) / 4005)²

Pstatic = 1.5 – ((600 / 2) / 4005)²

Pstatic = 1.5 – (300 / 4005)²

Pstatic = 1.5 – (0.0748)²

Pstatic = 1.5 – 0.0056

Pstatic ≈ 1.4944 in. wg

In this example, the calculated static pressure is approximately 1.4944 inches of water gauge.

FAQs

1. What is CFM?

CFM stands for cubic feet per minute and measures the airflow rate in HVAC systems.

2. Why is static pressure important in HVAC?

Static pressure indicates the resistance airflow encounters in a system, affecting performance and efficiency.

3. How do I measure total pressure (Ptotal)?

Total pressure can be measured using a manometer or pressure gauge installed in the ductwork.

4. What units are used for static pressure?

Static pressure is commonly measured in inches of water gauge (in. wg) or pascals (Pa).

5. Can I use this calculator for any type of duct?

Yes, the calculator can be used for various duct types and sizes as long as the required inputs are provided.

6. How does duct area (A) affect static pressure?

A larger duct area reduces resistance, typically resulting in lower static pressure for a given airflow rate.

7. What happens if my static pressure is too high?

High static pressure can indicate obstructions, undersized ducts, or improper system design, leading to inefficiencies.

8. Can this calculator help with system troubleshooting?

Yes, calculating static pressure can assist in diagnosing airflow issues and system performance.

9. What is the significance of a static pressure drop?

A static pressure drop indicates airflow resistance, which can impact the overall performance of HVAC systems.

10. How often should I check static pressure?

Regular monitoring of static pressure is recommended during system maintenance or when changes are made to the HVAC setup.

11. Can the CFM to Static Pressure Calculator be used for residential systems?

Yes, it is applicable for both residential and commercial HVAC systems.

12. Is the calculator accurate for all airflow conditions?

The accuracy of the calculator depends on precise input values; ensure measurements are taken correctly for reliable results.

13. What is the relationship between CFM and static pressure?

Generally, as CFM increases, static pressure also increases, reflecting greater resistance to airflow in the system.

14. How do I improve static pressure in my HVAC system?

Improving static pressure may involve resizing ducts, removing obstructions, or adjusting fan speeds.

15. What tools do I need to gather data for the calculator?

You will need a manometer or pressure gauge for measuring total pressure and a method to calculate or measure duct area.

16. Can this calculator be used for exhaust systems?

Yes, the calculator can be applied to exhaust systems, as static pressure is crucial for their proper operation.

17. How does temperature affect static pressure?

Temperature can affect air density, which in turn influences airflow and static pressure within the system.

18. What should I do if my static pressure readings are inconsistent?

Inconsistent readings may indicate measurement errors or changes in system performance; investigate potential issues in the ductwork or equipment.

19. Are there limits to using the calculator?

The calculator is most accurate within typical HVAC operating conditions; extreme cases may require additional analysis.

20. Can this calculator help in the design of new HVAC systems?

Yes, understanding the relationship between CFM and static pressure is critical in designing efficient HVAC systems.

Conclusion

The CFM to Static Pressure Calculator is a valuable tool for HVAC professionals looking to optimize system performance and ensure effective airflow. By understanding and calculating static pressure based on airflow measurements, users can make informed decisions about system design, troubleshooting, and maintenance. Regular use of this calculator will enhance the efficiency and reliability of HVAC systems, contributing to improved indoor air quality and comfort.