About Cooling Tower Capacity Calculator (Formula)

A Cooling Tower Capacity Calculator is an essential tool used to determine the cooling capacity of a tower in tons. This helps optimize water flow and temperature control in industrial and HVAC systems. Cooling towers work by transferring heat from water to the air, thus cooling it. The cooling capacity ensures the tower operates efficiently, preventing overheating and ensuring the process functions smoothly.

Formula

The formula for calculating the cooling tower capacity (CTC) is:

Cooling Tower Capacity (CTC) = (500 * Water Flow Rate * Temperature Difference) / 12,000

In this formula:

- Water Flow Rate refers to the rate of water flowing through the system, measured in gallons per minute (GPM).

- Temperature Difference is the difference between the water’s inlet and outlet temperatures, typically measured in degrees Fahrenheit (°F).

- 500 is a constant used to convert the result into BTU/min, and dividing by 12,000 converts this value into tons of cooling.

How to Use

Using the Cooling Tower Capacity Calculator is straightforward:

- Measure the Water Flow Rate: Find the flow rate of water passing through the cooling tower, typically given in GPM (gallons per minute).

- Record the Temperature Difference: Measure the difference between the inlet and outlet water temperatures in °F.

- Input the Values: Enter both the water flow rate and temperature difference into the calculator.

- Press Calculate: The calculator will use the formula to determine the cooling tower capacity in tons.

Example

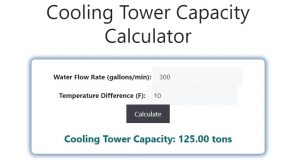

Imagine a cooling tower where the water flow rate is 300 GPM, and the temperature difference between the inlet and outlet water is 10°F.

Using the formula:

CTC = (500 * Water Flow Rate * Temperature Difference) / 12,000

CTC = (500 * 300 * 10) / 12,000

CTC = 12.5 tons

This means the cooling tower has a capacity of 12.5 tons.

FAQs

- What is the purpose of a cooling tower capacity calculator?

The calculator helps determine the cooling capacity of a tower in tons, ensuring efficient water cooling in industrial processes or HVAC systems. - Why is the water flow rate important?

Water flow rate directly influences the cooling capacity. A higher flow rate means more water is cooled, increasing the system’s efficiency. - What is the significance of the temperature difference in cooling towers?

The temperature difference between the inlet and outlet water helps calculate the heat loss, which is crucial for determining the tower’s cooling capacity. - What unit is cooling tower capacity measured in?

Cooling tower capacity is measured in tons. One ton of cooling equals 12,000 BTUs of heat removed per hour. - How accurate is a cooling tower capacity calculator?

The calculator provides an accurate estimate, but actual results may vary based on specific system conditions and efficiencies. - Can I use this calculator for residential cooling systems?

Yes, it can be used for both residential and industrial cooling systems, as long as you have the water flow rate and temperature difference data. - What is the constant 500 in the formula?

The constant 500 is used to convert the result into BTU/min, accounting for the specific heat capacity of water. - Why do we divide by 12,000 in the formula?

Dividing by 12,000 converts the BTU/min result into tons, which is the standard unit for cooling capacity. - Does water quality affect cooling tower capacity?

Yes, water quality can impact the efficiency of heat transfer, potentially affecting the cooling capacity of the tower. - What happens if my cooling tower capacity is too low?

If the cooling capacity is too low, the system may overheat, leading to reduced efficiency and potential damage to equipment. - What should I do if my cooling tower is oversized?

An oversized cooling tower can result in higher operational costs. In such cases, adjusting water flow rates or optimizing system settings might help. - Can I improve my cooling tower’s capacity?

Yes, you can improve cooling capacity by increasing water flow, lowering the inlet water temperature, or upgrading system components. - What is the role of BTUs in the cooling tower capacity calculation?

BTUs measure the amount of heat removed from the water. The cooling capacity calculation is based on removing 12,000 BTUs per hour for each ton of cooling. - Is cooling tower capacity related to HVAC performance?

Yes, cooling tower capacity plays a vital role in regulating the temperature of water used in HVAC systems, ensuring they operate efficiently. - What maintenance is required for a cooling tower?

Regular maintenance includes cleaning the tower, inspecting water flow rates, and ensuring temperature sensors are accurate. - How can I measure the water flow rate?

The water flow rate is typically measured using a flow meter installed in the system, which provides GPM readings. - What if my temperature difference fluctuates?

If the temperature difference fluctuates, you should take an average reading over time for more accurate capacity calculations. - How can I lower my cooling tower’s energy consumption?

Optimizing the water flow rate, regularly cleaning the system, and ensuring proper airflow can help lower energy consumption. - What factors affect the cooling tower’s efficiency?

Efficiency can be affected by water flow rate, air temperature, humidity, water quality, and the condition of the cooling tower. - Can I use this formula for other types of cooling systems?

While the formula is specific to cooling towers, it may be adapted for similar systems that involve water cooling, such as chillers or HVAC units.

Conclusion

A Cooling Tower Capacity Calculator simplifies the process of determining how much heat a cooling tower can remove from a system. By calculating the cooling tower’s capacity in tons, you can ensure optimal performance for industrial and HVAC systems, improving efficiency and preventing overheating. With accurate measurements of water flow rate and temperature difference, this calculator is an essential tool for system engineers and facility managers.